How does 3D printer work?

On previous articles we already enough in detail understood what is three-dimensional printer now the time is for acquaintance with its internal organization and principles of work of such equipment.

It is known today all devices of three-dimensional print are divided into industrial and portable equipment. They in many ways are different from each other; main principal difference is the purpose and size of the device. However the work of 3D printer regardless of its size and targeted application always is began with the draft. This draft is named 3D model. .

If there is picture of necessary object or figure it need be turned into volume image. To make it manually would be too long, so there is specialized software. It is able in a few minutes to simulate the subject of almost any complexity. Skills of user are very important here. In principle, the same can be turned and with help of the volume scanner, if you have any. Then he resulting object would be an exact copy of the original version.

When we speak about work with program for the simulation, the user can choose not only the most appropriate colors, but also the future texture. Formed virtual image is easy to do real with help of volume printing. Then 3D printer comes for help, today to buy it is enough easy if you have money. However it’s important this device can work differently and with using different materials.

The technologies of three-dimensional print

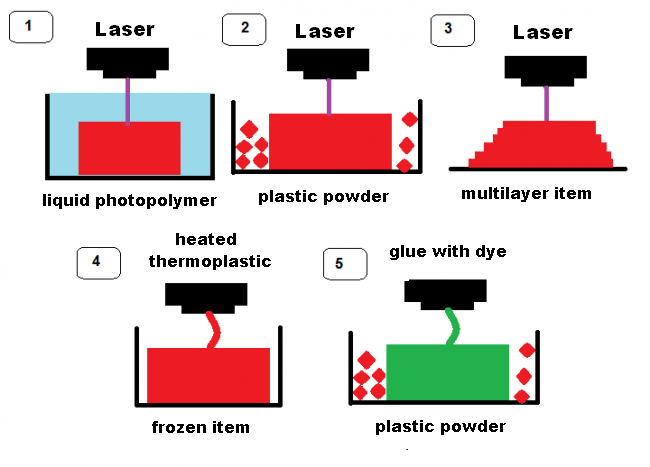

As usual printers, three-dimensional printing devices are represented by two types: inkjet and laser. Each these technologies work by its own separate principle. Laser 3D printers can work in three different directions:

- Illumination - in this case liquid photopolymer be careful treatment by the ultraviolet radiation, in result this material gets the set form and becomes solid. Received detail will be ready for practical application only after it is thoroughly washed from the remnants of photopolymer. Such 3D printer makes products of most different sizes and forms.

- The melting. This device uses powdered plastic with a low melting point, which is processed by a focused laser beam. All details and figures of given forms are made from the powder material. The finished product does not need to wash or to impose additional treatment before use, as the excess powder material can be easily removed using shaking. Such technology also is used 3D printer on metal.

- The lamination. Scientists compare this technology with the production of wafers, because there is observed layer-by-layer stacking of materials on each other. In result of repeating cycle of such procedures there is formed the volumes figure with unique turned layers and form. To print on 3D printer of such action may be electronic boards, plastic details or other elements.

Speaking about inkjet 3D printers implies two existing technologies volume printing:

- The modeling. Work of printing head of such device is a uniform distribution of the molten thermoplastic material on the surface of a working platform. Small droplets of material in a matter of seconds stick together with each other and instantly harden. To use such 3D printer is actually for production of different toys and strange figures.

- The klejka. As laser volume printers, inkjet analogues can use powdery substance as initial material. The difference between them is based on the fact that technology of work of inject 3D printer is closely related to the use of special glue, which in necessary quantity is in printing head of device. In process raising some figure in working chamber the powder mixture is bound with adhesive backing. As a rule, together with the adhesive backing in the working chamber is served and colored dye specified color.

How to classify three-dimensional printers

Given the fact that three-dimensional printers may be used in most different spheres of human activity it is not surprisingly they are divided into several specialized types:

- The 3D printer for consumers. These devices are enough compact tools with limited possibilities and speeds of order execution, and their minimal price is about 500 U.S. dollars. They can hardly be used in a serious production, but as a toy or personal hobbies they have no equal. However, it should not be forgotten that the used plastic rarely has high durability. The using this 3D printer is limited by amateur entertainment or production of colorful souvenirs.

- The professional 3D printer. The absolutely new level of volume print is showed by the professional aggregate for your attention. Its possibilities dozens of times exceed the "toy" consumer printers, but and minimal cost of such devices starts with the amount of 30 thousand American dollars. If you don’t know how works 3D printer of such scale, you will be surprised by its size and the level of noise that it makes. Its sizes can easily be compared with the cupboard, what is clearly to prevent the installation of such equipment in the home. Moreover, it is for use only by a trained operator, that also leads to additional costs forservice of device. However all your expenses will be warranted for the outstanding work and high quality of produced details, because to print on 3D printer of such scale may be most different objects, even more radically different from each other subjects simultaneously.

- the industrial 3D printer. This is the 3D printer, products of which really impress by their scale or Vice versa accuracy and quality of the smallest details. It may be 3D printer on metal or any other devices of volume print, which can work at maximum speeds with the highest quality of products. Here we speak not so much about the production of several details at the same time, many of the mass stamping of objects. There is hardly a task or the figure with which the industrial 3D printer would not be able to cope. Such aggregates practically isn’t needed rest, they can work around the clock and increase productivity of enterprise even when its owner sees sweet dreams. For these monsters aren’t been limits in using of working materials, therefore they easily cope with plastic and titanium alloys. Of course, the cost of such printers is very high – from three hundred thousand American dollars.

Pic. 5. The consumers’ three-dimensional printer

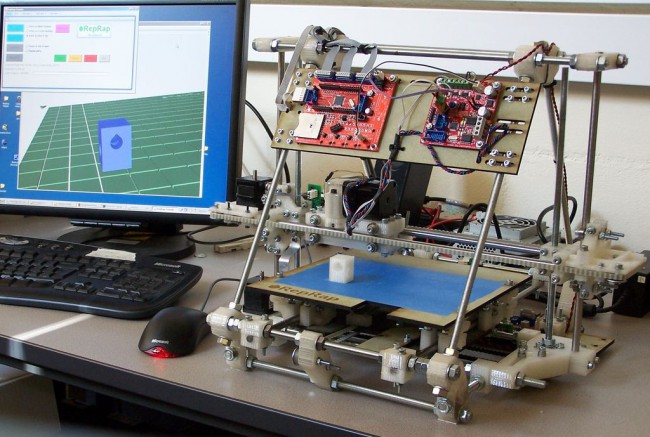

Pic. 6. The professional 3D printer

The exhibition of 3D printers in Moscow

Not long ago in Moscow was been the serious exhibition of electronic devices of volume printing. It was back in the beginning of 2014 in one of the Moscow exhibition and Convention centers. It must be said that this event was really memorable and interesting, because its visitors were able to meet for the first time with abilities of volume print.

This arrangement was lasted for two days, and to visit it could be everyone. Many people were able not only to know what 3D printer is, but also get a lot of useful information for the development of their own business. The exhibition of 3D printers in Moscow was especially interested representatives of jewelry, some businessmen, designers, medical workers and cooks. The purpose of this exhibition was the establishing relations with customers and acquaintance with the latest production technologies of production. Youthful and experienced developers tried to demonstrate the incredible work of their inventions, which, of course, added the bright colors to this event.

Advantages of 3D printers

Devices of volume print little by little are wining all world, they are used in most different spheres of activity. They have learned to save lives and even create new organs, and with their help enterprises go on a completely new production levels…. So in what is special working 3D printer, what are its advantages over the earlier equipment? To answer this question, it is enough to get acquainted with possibilities of 3D printers:

- Recreation of volume figure or object of any complicacy occurs in five or even ten times faster than with using other methods.

- Because of the multifunction of such aggregates, one device will be enough to meet the needs of small enterprise.

- There is no need separate painting of a detail, because the dye is simply mixed into the composition of the building mix.

- The representation of logo and additional marketing solutions will not be difficult, because they can be applied in the production process.

- Even smallest details of model or any other complex industrial object will be executed with maximum precision and in the shortest terms.

- For the user of the aggregate are available all colors for painting of any object without exception, their brightness and saturation can be adjusted easily.

- The cost of service such equipment is record low in comparison with other methods of production.

- This production may be truly named waste, because the material, remaining after the preceding order, can be used in the following one.

- There is no need for long-term training personal, because such equipment is enough simple in exploitation.

- The using of ecologically pure materials make working with this unit truly safe and fun.

Despite the fact that a 3D printer to buy can afford not every entrepreneur because of its high cost; this purchase can be a really profitable investment.