How to choose and buy a 3d printer?

As the three-dimensional print takes root little by little in almost all spheres of human activity the purchase of 3D printer has long been of interest to many of us. If five years ago we heard about such elaboration as about interesting innovation from news, then today developers produced millions of various models of three-dimensional printing machines, which able to meet the requirements of each one. However from this variety is arisen a question how to choose exactly what you need and to keep within the available budget. That is exactly what we will discuss in this article.

How to choose 3D printer

Choosing such device, user need to clarify for what he plans using it and to designate most appropriate technology of three-dimensional print, namely from this will be depended on necessary material and quality of produced things. The choice of STL model for 3D printer is secondary question in this case. You should pay attention on the following factors

- What initial materials suit for recreation of figures and objects with help this equipment.

- The print format. If user plans to create large-scale objects or models of entire buildings he will certainly need a device running three-dimensional large-format plotter. Otherwise will be enough and more simple models.

- The exactness. When we speak, for example, about dental prosthetics or jewelry work every very small detail must be done ideally, then the customer should pay attention only to 3D printers, which have high accuracy.

- The thickness of print layer. The smaller its value, the better and more accurate will be the details.

- The compatibility of device with most popular software. If 3D printer supports only own software user can have many problems in process of connecting this device to the computer. The user will have not only a 3D printer to buy, but also to pay for expensive software tool.

- The speed of print. The large-scale production. Making such a purchase, you shall take into account the time necessary to produce one object. If it takes a several hours the owner of the enterprise will definitely suffer serious losses, therefore speeds of work must be quick enough. As a rule, any industrial 3D printer meets all of these requirements

- The simplicity and the comfort in the process of exploitation. In this case the user must be guided by his personal preferences, because namely he will work with this 3D printer. .

- Dimensions and mass of future articles This is not the least of the factors, because compact three-dimensional consumer printer obviously is not suitable for the creation of car parts, and the purchase of expensive professional equipment is not obligatory at all, when we speak about creating small souvenirs. If you plan to use 3D printer on metal then its work site must be big and powerful.

To buy 3D printer in Moscow or other city you can without much difficulty, but before making such purchase the consumer should definitely assess the planned volumes of the performed works. The competent estimation of own needs allow choosing a right aggregate. In order to do this, you need a rough estimate of the numberof volume details, which you must produce in three months. Based on this analysis, you can decide if a 3D printer is needed to a man at all, because such device should be repaid even a little for this period of time.

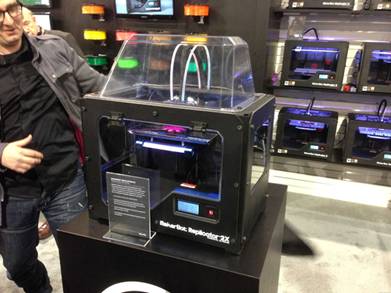

Pic. 1. The three-dimensional printers and their goods.

The cost of 3D printer

We already know the device for a volume print is incredibly expensive. However the cost such apparatuses may be very different, because it depends on purpose of such printer, the complexity of the service, its functional possibilities and speed of production. Then how much does 3D printer cost? Let’s go for a starting price of each type of apparatusof three-dimensional print :

- The consumers’ The every desiring can afford to buy such 3D printer, its cost is about 500 American dollars and more. Because at this stage of technology development huge attention is paid to the device of volume printing soon they can be less expensive. .

- The professional. Such device have much more possibilities then the previous, it can do several difficult tasks at the same time. It is practically universal 3D printer. Its cost starts with thirty thousand dollars.

- The industrial three-dimensional printer is ideal device for full automation of manufacture and increasing in volumes of products. Users usually buy such aggregates for their plants or factories, such wonder costs not less than 300 thousand dollars. Some industrial 3D printers cost their owners in a million American dollars, but bring them much more financial benefits.

The plastic for 3D printer you can buy in any city with help most different internet-shops. Moreover in set with such device always is bought the complete set of the necessary equipment and materials, which should be enough for quite a long period of time. Therefore you will need take care of purchase new portion of plastic much later. The cost of the 3D printer from maintenance of such equipment depends on the complexity of the purchased device. With consumer’s plants may be understood everyone, but more complicated models of professional and industrial machines demand some volume of additional knowledge, so trained operator.

Where can you buy three-dimensional printer

Of course today leaders of production 3D printers are United States of America and China. America punches more new aggregates, and Chinese skillfully do over again their elaborations by new names and so cheap models from China rarely have high quality.

Namely American producers are considered best in this sphere. For an example, a good representative of inexpensive professional 3D printers is considered a trademark MakerBot. Such 3D printers are able to do simultaneously several details from different materials; their cost is a maximum of $ 5,000. This company produces industrial machines too; their cost is more than 100 000 dollars. Here you can also include a 3D printer on the metal and many other more complex machines.

Pic. 2. The contemporary three-dimensional printer MakerBot Replicator 2

The industrial 3D printer or consumers model of such device is better to buy in specialized stores, because to order they straight form USA or China may be problematical and expensive because of customs duties, which sometimes result in overpayment in the amount of thirty percent of the total cost of the printer. Stop attention on those organizations that have the corresponding certificates and positive feedback. More in detail about this you can learn on the user’s forums.

Most popular 3D printers of the present

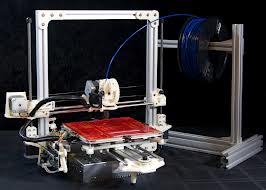

- Bukobot - production Deezmaker. This is consumers’ model, which uses ABC-plastic and PLA as initial materials. Device’s possibilities allow recreating simple engineering designs and their prototypes. There is enormous number of product’s work modifications. Such 3D printer may be bought by 600 dollars, if we speak about the basic configuration. Devices with advanced features may be cost differently, but not more 3000 dollars.

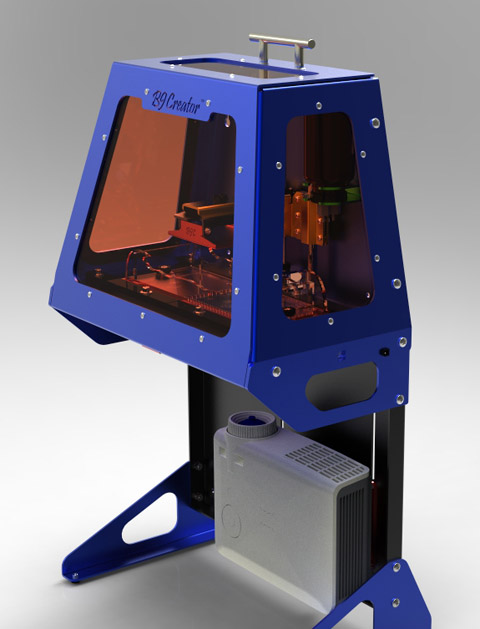

- B9Creator is next American elaboration. For it is prophesied a big future in sphere of dental prosthetics, because its work tools can make even most subtle and intricate objects with surprising accuracy. Since this device appeared recently, in the middle of 2013, to buy such 3D printer in Moscow may be problematic still. However soon it is planed to correct the situation. The cost is about 6000 dollars.

Pic. 4. The professional volume printer B9Creator

Also it can be used in jewelry business successfully.

- Object30 Pro is multifunctional 3D printer, which can produce things from seven different materials. When you’ll learn how much such printer cost you will agree this device is not cheap. The price starts at $ 20,000.

- ZPrinter 450 is one from most of the brightest representatives of contemporary industrial three-dimensional printers. It is namely that 3D printer, which have best responses. With maximal exactness and enough high speed this device makes details and objects of any complexity from practically any material. In addition, among other advantages it has the excellent color quality. Such aggregate cost not less than 50 000 dollars.

Pic. 3. The consumers’ three-dimensional printer Bukobot

Pic. 5. The jewelry, made with help device of volume printing B9Creator

Pic. 6. The 3D printer Object30 Pro

Pic. 7. The industrial device of volume printing ZPrinter 450

Is it possible to make a 3D printer own hands

Many people try to make the device of volume printing at home and not seldom they have success. However we should not flatter ourselves with the hope about making great professional aggregate with a wide range of possibilities at home. Home-made models of 3D printers are something special and even sacral for their creator, but on practice their using is enough limited and their functionality is record low. Such device is useful only for fun or some researches, but not for serious purposes. Namely therefore if you need 3D printer it is better to buy it in specialized shops.

It is proved by a number of deficiencies, the so-called improvised devices volume printing:

- The limited permission. The size of the nozzle physically will not allow the user to create miniature details or on the contrary scale constructions. This means that he will have to recreate some parts, and then glue them manually.

- The lack of cooling system. At home is practically unreal to make the device, which able in a few minutes to cool each of the applied layer reproduced object, but without this you can spoil detail. If the operator will have to stop operation of the printer to cool down each layer, work will take several days or even weeks.

- Additional complications in process making of overhanging elements. Unprofessional device can hardly cope with this task without damaging the created object.

- The low quality of work result. In this case is impossible to achieve high quality and accurate. The material may be distributed not enough evenly, and it’s difficult to make ideal smooth surface, so after a long process of manufacturing of three-dimensional figure, the user will have a lot to finish by hand.

In that way we can do conclusion, primitive home-made three-dimensional printers can’t be used in work. However such apparatuses can be a wonderful pastime or hobby. It may be enough difficult to choose the plastic for 3D printer, to buy usual ABC-plastic is not decision of problem. Yes and STL models for 3D printer of home production should work much more thoroughly. And in the case of software, the developer enthusiast can also expect some difficulties.

The purchase of three-dimensional printer demands considerable financial expenditures, but if you have found exactly what you need, then as soon as possible this acquisition not only pay off, but will bring you a fortune. Our future is in hands of technology, which is named 3D printer, feedback from users and experts on this issue differ considerably from each other, but they all agree that today these machines are open before one unlimited opportunities.