How to serve 3D printer?

For those people, who plans to purchase a three-dimensional printer, or only thinks of such acquisition, there is the issue of service this device. Because taking of decision depends mainly on complexity and cost of printer. In this article we will try to investigate in detail what materials and knowledge are necessary to user for guaranteeing work of 3D printer. .

Materials, used for three-dimensional print

- ABC-plastic. This name is simplified variant, because chemists name this substance by acrylonitrilbutadienstyrol. This material has high durability and enough the level of elasticity. In sphere of three-dimensional print is widely used powder blend of ABC-plastic, when volume products are produced by the method of filling extrudable melt. The plastic for 3D printer is one from most durable industrial materials, but under the influence of sun rays he quickly destroyed. This material is absolutely not fitted for recreating transparent objects. To buy plastic for 3D printer may be in specialized shops or you may order it via the Internet.

- The polycaprolactone is known as one from more perspective and demanded material for three-dimensional print. It may be used in several technologies: selective laser sintering, fill extrudable melt and others. A distinctive feature of the given substance can be considered a low melting point, which is successfully combined with a high rate of solidification. And what is more, its chemical composition is absolutely harmless for human’s organism and differ unprecedented resistance.

- The Low-pressure polyethylene. This substance has long been considered as one of the most popular types of plastic in the world, namely therefore it is not surprisingly that developers of three-dimensional printers have found a use for it in this field. All of us know how look like a plastic bag, plastic bottles and other items from food plastic. All this is low-pressure polyethylene, which is today one of the recognized leaders in the field of volume printing. Another factor that contributes to such a wide use of this substance is that it is suitable for any technology of volume print.Only few material have the same universal properties, but the advantage of polyethylene is its low cost.

Pic. 1. Coils of colored plastic ABC

Pic. 2. The material of polycaprolactone

Pic. 3. The Low-pressure polyethylene

What do you need for filling 3D printer

The process of refueling a three-dimensional printer is a little distinguished from simple two-dimensional inkjet print device type. It should be noted that "ink" 3D printers is enough for a long time, therefore to carry out this procedure often you don't have. Answering the question, what you need to fill a 3D printer that is first of all to think about the purpose of using this device. The most popular material has always been and remains the plastic for 3D printer, which may be bought in specialized shops or in internet on sites of manufacturers.

You can fill three-dimensional print device and other materials, all demand on recreating object. Today are known culinary 3D printers, which are filled by food products. Some three-dimensional devices on the basis of stem cells from human or animal recreates real living organs, ready for transplant. It is clear that the plastic for 3D printer, producing machine parts and metal structures, will not work. Industrial devices if three-dimensional print at all can "eat" any material and simpler units operate with a limited number of substances.

As a rule the inkjet 3D printer is sold complete with coil of specialized plastic and a set of necessary tools. Depending on that, how much is a 3D printer; these kits can be quite impressive or consist of only the most necessary items. Three working platforms and special gloves for the safe operation of the devices are also often included in this kit. In addition, each separate model of the three-dimensional printing device comes with a detailed instruction, in which with help of the detailed description of the device and clear images is explained the process of a refueling unit and many other useful things.

The software of three-dimensional printers

In itself, the device of volume printing will not function, because all processes of working chamber of such printer are based on a particular software tool. The specificity of his work is that it must design a three-dimensional image or shape instead of a flat image. Moreover, models for 3D printer must be a perfect virtual version of the future project, because namely they are guided by the three-dimensional printer in the future. Every detail and exquisite contour must be produced with maximum accuracy, as this determines the quality of production.

No matter how much is a 3D printer, it is in any case requires the software which in turn is subdivided into several types:

- Programs for management of printer’s work ;

- Three-dimensional editors, which are responsible for performing specific tasks by device.

It’s important these programs were made in accordance with existing norms and standards. This will depend on as in fact works 3D printer, products, or rather their quality and precision, and much more. Among the most important features of such software it is worth noting the data formats that they need to read and edit:

- STL is the specialized programming language, which to describe the planes of the specified object uses triangles; ;

- X3D. This language is based on the so-called XML standard, according to which the countdown is on a pre-specified data profile;

- VRML. It’s based on triangles, which have no common vertices. .

The creation of three-dimensional figures with help of volume print is begun with the fact that formed STL models for 3D printer. They give to operator all necessary information about creating object. Elaboration of STL model for 3D printer, as a rule, is conducted with the help of CAD programs. It must be said that such software is quite expensive. If good 3D printer to buy at low cost can be quite difficult, then with similar software observed bit different picture. Of course, when we speak about scale production it makes no sense to save on specialized programs. However most of the necessary functions can be carried out and by a free Google SketchUp.

The three-dimensional editor Google SketchUp

As the practice show, the using this program is deal for work of portable and even some professional three-dimensional printers. Its peculiarity is that all models are created in the native program format, but after all the work they are converted into STL. Software from Google SketchUp has convenient interface and a number of effective business tools that work 3D printer is greatly simplified:

- There is special software tool capable of only a few clicks to convert a flat surface in three-dimensional image.

- The high accuracy of of observance of the submitted data and settings allows you to create a 3D printer products with the highest level of compliance virtual model of the obtained product.

- This software works with many other programs, for example - AutoCAD, where you can transfer the different geometric characteristics of the created object.

- If it’s necessary for transformation of two-dimensional plane in volume figure you can use function "extrusion", which is ideal for 3D printer, working on principle of extrusion.

- .

- The user can see what it looks like one or another part of the created object in the section.

- Another interesting and popular function of this editor may be considered the advanced capabilities of the operator to view and display models. Any selected aspect may be kept in separate folder, and you can rotate the obtained model in different planes.

- To produce internal examination of the reproducing object you can do absolutely at any stage of work.

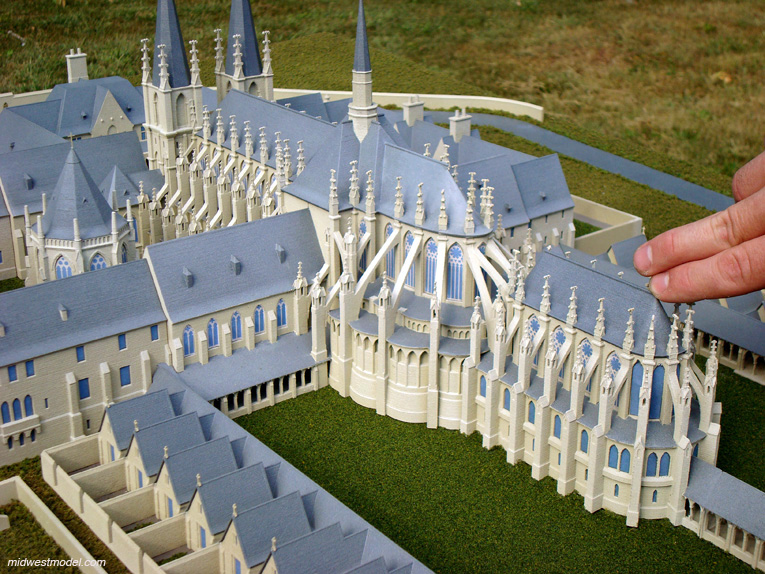

- With help of this program you can create scale models with most different elements. Each such site can be assigned to specific parameters and physical qualities. Such models for 3D printer you can see on picture below.

- The program supports many other formats of models, therefore the person can without ceremony import any additional element from some object. The same applies to different images in most popular formats (JPG, PDF, PNG and others).

- It is permitted the export raster images in most different formats, if the size does not exceed ten thousand pixels.

Pic. 4. The model of lock, made with help of three-dimensional printer

Most popular 3Deditors of the present

Besides Google SketchUp there are many useful programs for realizing of three-dimensional print, which meet all required standards. We already understand, to buy 3D printer means to do only half the story. Today are elaborated enough many software tools that help to simplify and to control 3D printing.

- ZPrint is enough not bad program for volume print, possessing a standard set of functions. It supports the work of three-dimensional printers of Z-Corporation’s production.

- ZEdit. With this software user’s possibilities are much broader, thanks additional services:

- Materialise Magics is the service that controls the appearance of defects in the products and helps to eliminate them. The correction of errors is at the stage of recreating the virtual model. If STL-models are loaded in the program already in a ready kind then it can analyze it for errors and malfunctions.

- Tinkercad. This program allows the person to recreate desired object right in his browser without having to install some application. It work with most different 3D printers, and also supports mobile device or tablets. What about the cost of using this software it is completely free for any user.

- SolidWorks Standart is interesting work tool, which allows the user to simulate the object or set of objects of different complexity. It permits the planning of figures or objects with taking into account the characteristics of the future of used materials, for example, metallic constructions or plastic details. It is considered one from most convenient software in its field and is easy to control.

- OpenSCAD is specialized work tool, which is dedicated exclusively to the production of solid state volume objects and figures. This technology is most often used for the design and production of parts of vehicles and aircrafts. It supports 3D printers, operating on the principle of extrusion.

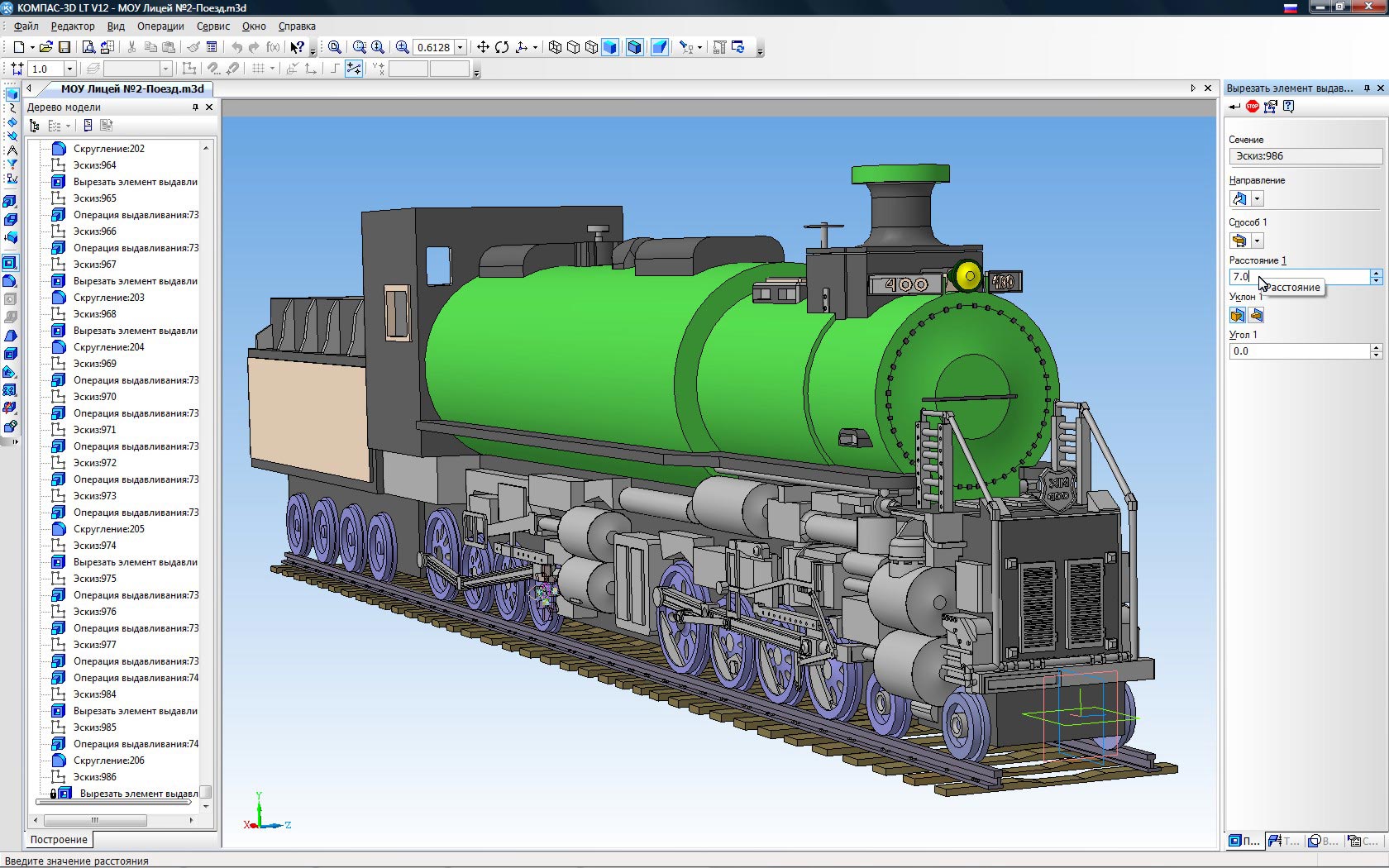

- Compass 3D is universal software, which is being used mainly in the field of modeling of communications. The program allow at the same time to monitor the change and the work of each individual element of the system, to recreate scale operating models of entire buildings or heavy machinery, and further to carry out their immediate construction. Contemporary systems of electricity supply in most cases use this software. With it practically any 3D printer can work, photo specified below will show you the features of this program in more detail.

- T-FLEX CAD 3D is for automation of technological and design parts of production. All working tools of program are of high accuracy and reliability, and the capacity of such software will be enough for the uninterrupted twenty-four-hours work of industrial 3D printer, photos of which you can see below.

Pic. 5. The construction of the volume model in the program Compass 3D

Pic. 6. The industrial 3D printer

The person who tries to find a suitable three-dimensional printer for his business should pay attention to possibilities of the software, which could best meet his needs, because namely from it and will depend on the quality and speed of implementation of future tasks. The efficiency of 3D printer mainly depends on selected software by user.